We seek to ensure the products we sell are sourced responsibly, upholding human rights and workplace best practices.

Our Commitment

We expect that all merchandise offered by Qurate Retail Group is produced by business partners who share our commitment to corporate responsibility. We will only conduct business with suppliers who comply with our Global Business Partner Code of Conduct, which requires products be produced in conditions that support:

- Human Rights

- Fair Labor Standards

- Employee Safety

- Environmental Stewardship

Read more about our Sourcing Social Responsibility (SSR) program

This commitment to global human and labor rights and our program for verifying that our products are made in safe and responsible facilities, aligns with the United Nations Sustainable Development Goals 8 and 12.

Our Strategy

Qurate Retail Group has a 4-part responsible sourcing strategy to address supply chain risks:

- Code of Conduct

Establishes Qurate Retail’s requirements for business associates on social and environmental issues through its Global Business Partner Code of Conduct. - Risk Evaluation

Qurate Retail evaluates the risks of our vendors based on several criteria. - Enforcement

Qurate Retail conducts audits of certain vendors according to a risk-based methodology and reserves the right to audit all vendor factories to confirm that they comply with the Global Business Partner Code of Conduct. - Team Member Training and Accountability

Global sourcing staff and others who are involved in sourcing activities are trained on Qurate Retail’s sourcing policies and procedures and are accountable for complying with such company policies and procedures.

Code of Conduct

We expect all of Qurate Retail’s vendors and their suppliers of finished goods to comply with our Global Business Partner Code of Conduct, which is incorporated by reference into each of our purchase orders or similar agreements. These standards are mandatory for all of our suppliers.

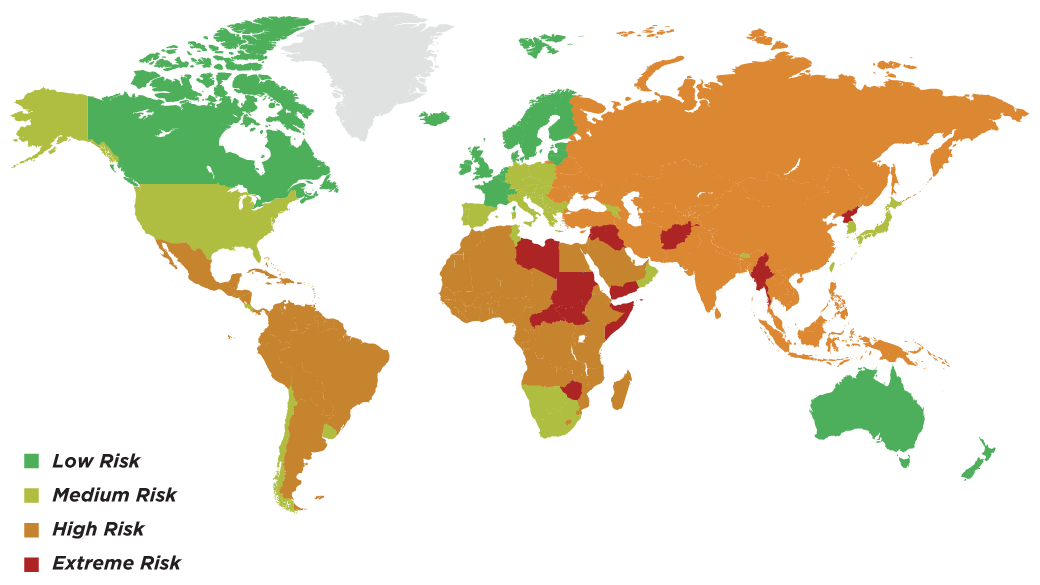

Risk Evaluation - at the country level

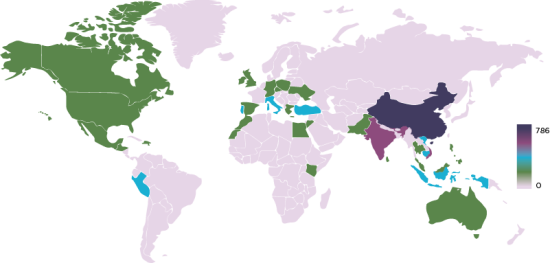

Qurate Retail uses a risk-based approach to determine the scope of our Sourcing Social Responsibility (SSR) program - which audits manufacturers of our finished goods (factories) around the world. A key element of this approach is represented by a manufacturing country risk assessment, so that we focus our efforts and resources in the sourcing regions with greater levels of concern. We do not knowingly engage with factories in high-risk areas known for forced, undocumented, child or other illegal labor.

Under this approach, our SSR program targets all our proprietary brands’ factories and the top market-vendors that we do business with at QVC (US, Germany, UK, Italy), and HSN. Starting in 2021, we began the process of expanding the scope of our current SSR Program beyond manufacturers of finished goods in order to gain visibility of the various entities involved in the manufacturing supply chain including, in some cases, raw materials.

Country Risk Assessment

Source: Corruption Perception Index

Risk Evaluation - at the factory level

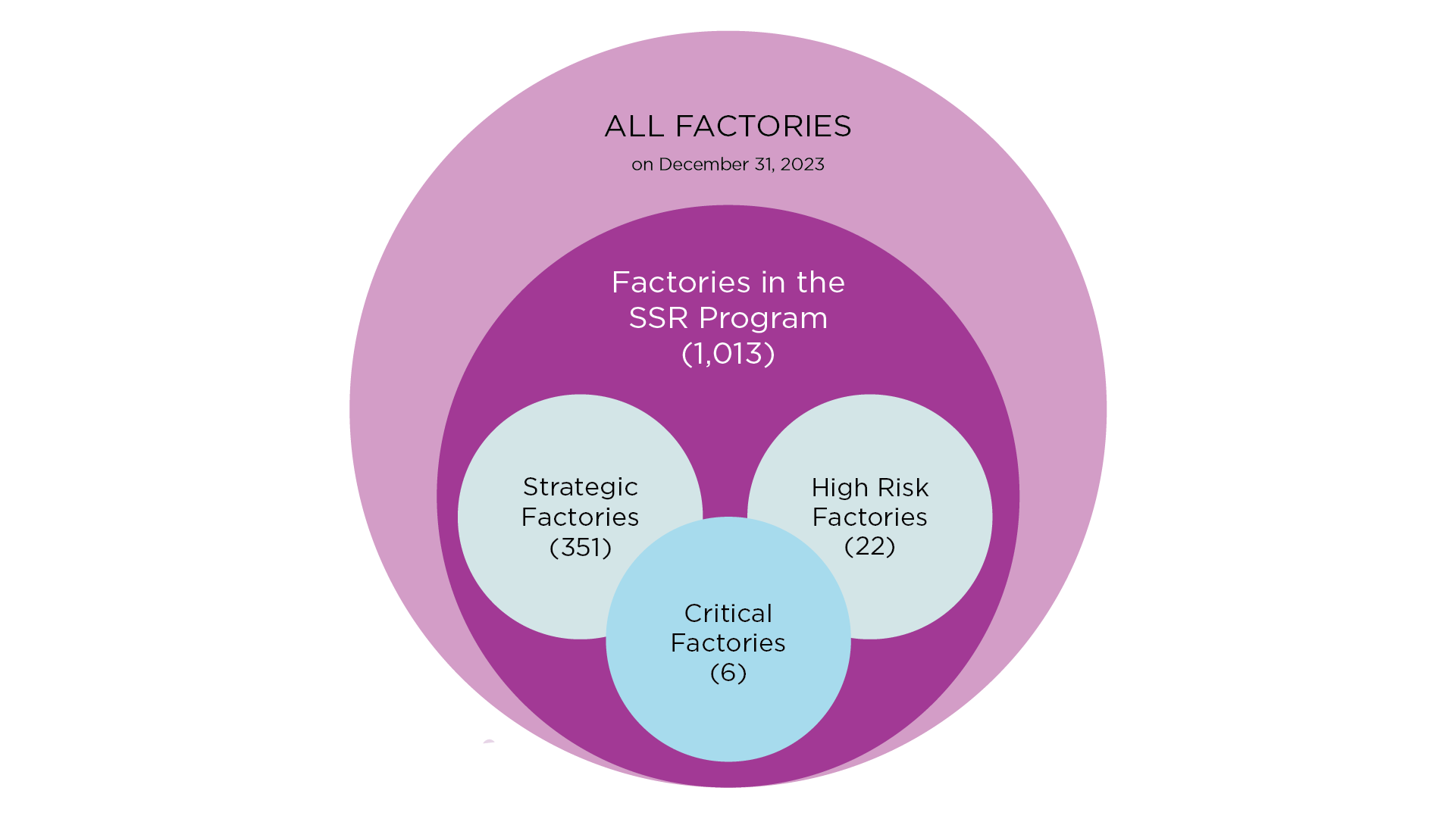

Risk is also assessed at the factory level. Because of the large number of individual suppliers we source our merchandise from, we take a variable, risk-based approach to auditing companies within our supplier base. A number of factors are used to evaluate which of these suppliers will be subject to a factory audit. These factors include: geographic location, the volume of purchases from the market-vendors (the top 70% value threshold for market-vendors for QVC US, Germany, UK, Italy, and HSN), and whether the product is a proprietary or exclusive brand to Qurate Retail Group.

Within this framework, we group our suppliers into certain categories to determine how to best deploy our auditing capabilities and minimize the greatest risks in our supply chain:

- Strategic Factories – are those manufacturing our Proprietary Brands (Private Label) and Exclusive products.

- High Risk Factories – are those scoring very low during a factory audit.

- Critical Factories – are our strategic factories that are high-risk factories as a result of scoring very low on the factory audit.

Enforcement - through factory audits

We have an enforcement program for our vendors and their factories that produce finished goods. Our Sourcing Social Responsibility (SSR) program verifies supplier compliance with our Global Business Partner Code of Conduct through periodic factory inspections by a third-party certification company. Intertek is our exclusive auditing company to carry out Workplace Conditions Assessment (WCA) audits for our factories around the globe. Our SSR Team audits Intertek on a regular basis to verify the quality and consistency of the WCA audit services they provide.

The WCA audit take place at periodic intervals (ranging from every year to every two years) against the 5 areas of risk, shown below. Each report resulting from an audit includes a score for each of the five areas which are benchmarked against global, country and industry scores. And for each country where one of our manufacturers is being audited, Intertek also prepares periodic country-level audit reports benchmarking that country in these same 5 areas of risk.

Labor

Child/Forced Labor

Discrimination

Discipline

Harassment/Abuse

Freedom of Association

Labor Contracts

Wages & Hours

Wages

Benefits

Working Hours

Overtime

Minimum Wages

Rest Days

Health & Safety

Occupational Injury

Machine Safety

Fire Hazards

General Work Facility

Emergency Preparedness

Management Systems

Documentation

Records

Worker Feedback

Participation

Internal CAP Processes

Environment

Waste & Air Emissions

Legal Compliance

Environmental

Management Systems

Chemical Handling

Enforcement - through factory audits

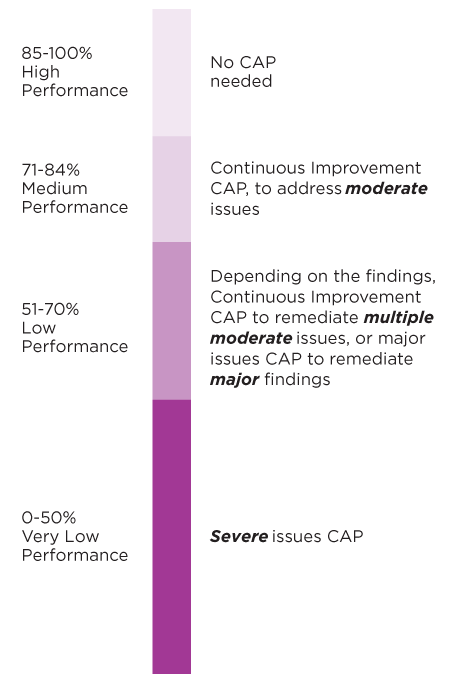

All factory audits with moderate, major or severe issues require a Corrective Action Plan (CAP) to be implemented by the manufacturer, and then validated with a follow-up audit conducted by Qurate Retail’s SSR team.

Major/Severe issues CAP are developed to address major or severe audit findings: if a factory does not implement the CAP within the timeline agreed upon, we stop doing business with the factory. Continuous Improvement CAP are issued to address moderate findings.

If a Strategic factory scores a very low rate during the audit, the CAP implementation is also coupled with a Business Continuity Plan, factory support and education events conducted by our SSR team. These internal resources are provided to the factory with the purpose of ensuring the factory is capable to develop long term plans for sustained compliance.

Qurate Retail’s SSR team also carries out announced, semi-announced and unannounced audits to ensure factories maintain a satisfactory

level of compliance between full audits. In addition, the SSR team conducts monthly seminars to ensure our manufacturers understand our expectations and their obligations regarding remediation plans.

Rating and Review

Each audit report assigns a rating which informs any action needed and allows our team to focus on the factories that require greater attention to remediation.

WCA Audit Performance Scoring Scale

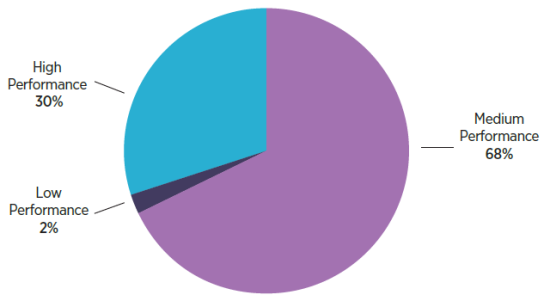

2023 Scoring Performance

(out of 961 audits completed)

Team Member Training & Accountability

Global sourcing staff and others who are indirectly involved in sourcing activities have been trained on Qurate Retail’s sourcing policies and procedures and are held accountable for complying with such company policies and procedures. Training occurs every 2 years, where team members learn about our ethical sourcing commitment and why ethical sourcing is important. At the end of the training, they are more attentive to potential risks and issues that they may encounter in their jobs, what their role is in helping us source product ethically, and what to do if, for whatever reason, they find evidence of unethical practices in our supply chain.

More About Our Supply Chain

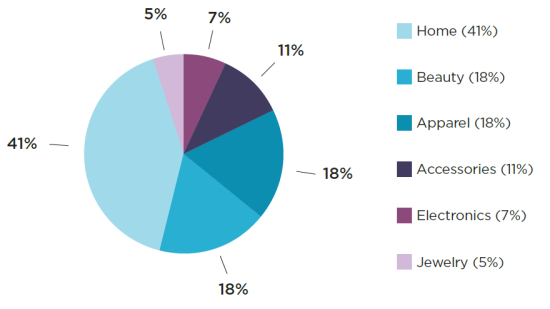

Merchandise Mix

as of December 31, 2023

Cost of Goods Sourced*

Percentage of Cost of Goods by Merchandising Mix

* This data is for QVC, Inc. which includes HSN, QVC US, and QVC International

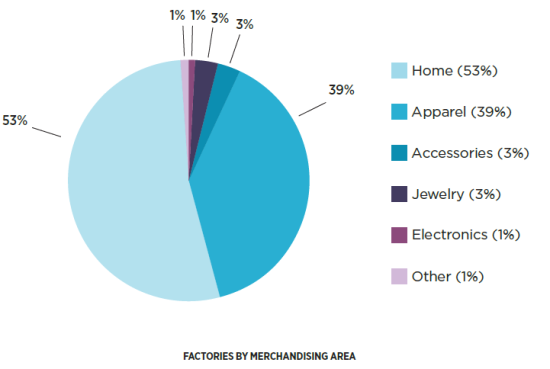

Manufacturers (Factories)

Covered by the SSR Program

(Total: 1,013)

as of December 31, 2023

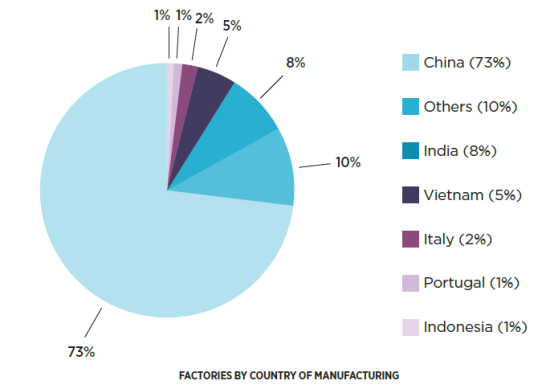

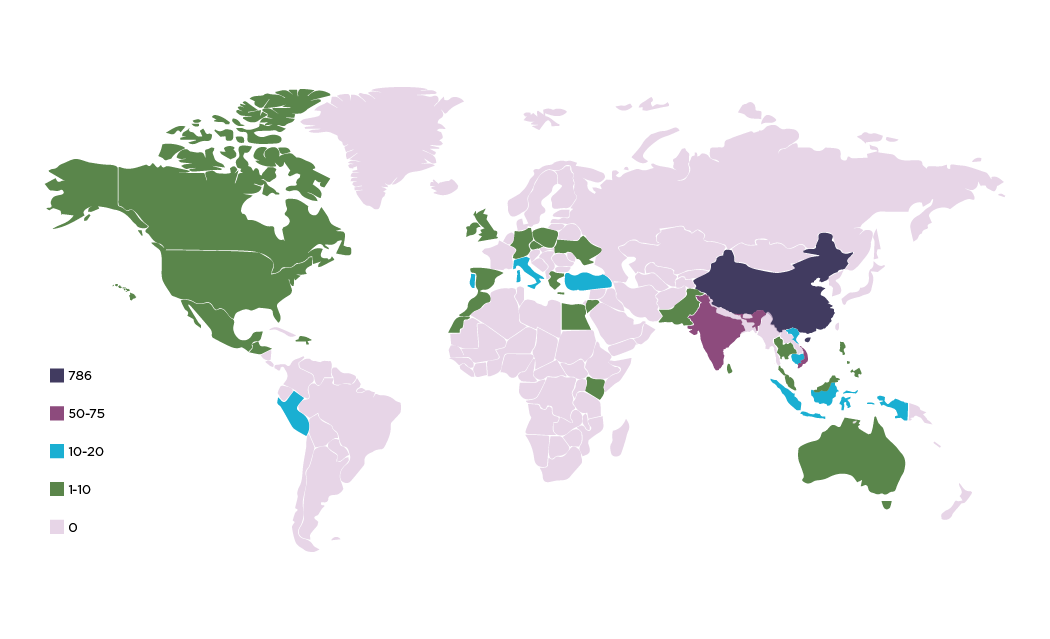

*Others include: Australia, Bangladesh, Canada, Cambodia, Czech Republic, Dominican Republic, Egypt, Germany, Greece, Guatemala, Ireland, Jordan, Kenya, Malaysia, Mexico, Morocco, Pakistan, Peru, Philippines, Poland, Spain, Sri Lanka, Thailand, Turkey, United Kingdom, Ukraine, and United States.

1,013 Manufacturers (Factories)

in 33 Countries

as of December 31, 2023

2023 Metrics

| Number of factories subject to the SSR Program | 1,013 |

| Number of audits completed in 2023 | 961 |

| Number of Strategic Factories in the SSR Program | 351 |

| Number of audits completed at Strategic Factories in 2023 | 337 |

| Number of CAP implemented in 2023 | 616 |

| Severe/Major CAP (82 factories) | 76% CAP completed | |

| Continuous Improvement CAP (534 factories) | 94% CAP completed |

| Number of factories rated as High Risk | 22 |

| Number of High-Risk factories (part of the 22) we stopped doing business with | 2 |

| Number of factories classified as Critical* | 6 |

*Strategic factories which are subject to a corrective action plan are deemed “critical” until the plan is executed, and a subsequent audit is passed. Therefore, the “critical” designation is a transitory status, and the number of critical factories will change over time depending on the status of all strategic factories. This figure represents those factories with critical status on December 31, 2023.

Definitions

- Strategic Factories

Those manufacturing our Proprietary Brands (Private Label) and Exclusive products - High Risk Factories

Those scoring very low during a factory audit - Critical Factories

Our strategic factories that are High-Risk factories because of scoring very low on the factory audit - Severe/Major CAP

Corrective Action Plan for all factories found to have major or severe issues during a factory audit - Continuous Improvement CAP

Corrective Action Plan for all factories found to have moderate issues during a factory audit - Factory

Manufacturer of finished goods

Tier 1 factories who produce apparel and/or home products direct-sourced and sold at retail by QVC and HSN (as of December 12, 2023).